Triol AT27 variable frequency drives in the metallurgy industry

The wide variety of technological processes in the production of metallurgical products imposes different requirements on the equipment involved. In the production of metal products, the most important processes are ore preparation, coke production, ore smelting, metal casting, and rolling.

The use of a medium-voltage variable frequency drive is possible in each of the above stages, but in our opinion, the highest requirements are placed on the variable frequency drives involved in the final stage of production – rolling. It is the control of the roll drive in a rolling mill that largely determines the quality of the final product and its assortment.

Despite their common purpose, rolling mills differ in design, rolling method, and operating features.

Rolling mills

Depending on the product they produce, rolling mills can be divided into:

- cogging mills (blooming mills, slabbing mills);

- billet mills;

- rail and beam mills;

- sections (heavy, medium, and small sections);

- wire rod mills (for wire rod production);

- plate rolling (for thick, medium, and thin sheets);

- tube-rolling;

- wheel and tire rolling mills;

- mills for special types of rolled products.

The main mechanisms of rolling mills are the rolls of the working stands.

The roll drives can be divided according to the direction of rotation into:

- non-reversible;

- reversible. and the number of motors:

- single-motor;

- twin-engine.

Our challenges

-

A non-stop process.

-

Integration with the process control system.

-

Service life extension.

-

Rolling direction reversal and spindle positioning.

-

Optimization of energy consumption and electromagnetic compatibility.

-

Operation in high dust and conductive dust environments.

-

Efficient operation in twin-motor mode.

-

Placement in confined spaces.

-

Adaptable to local ventilation and equipment maintenance possibilities.

Our solutions

1. A non-stop process.

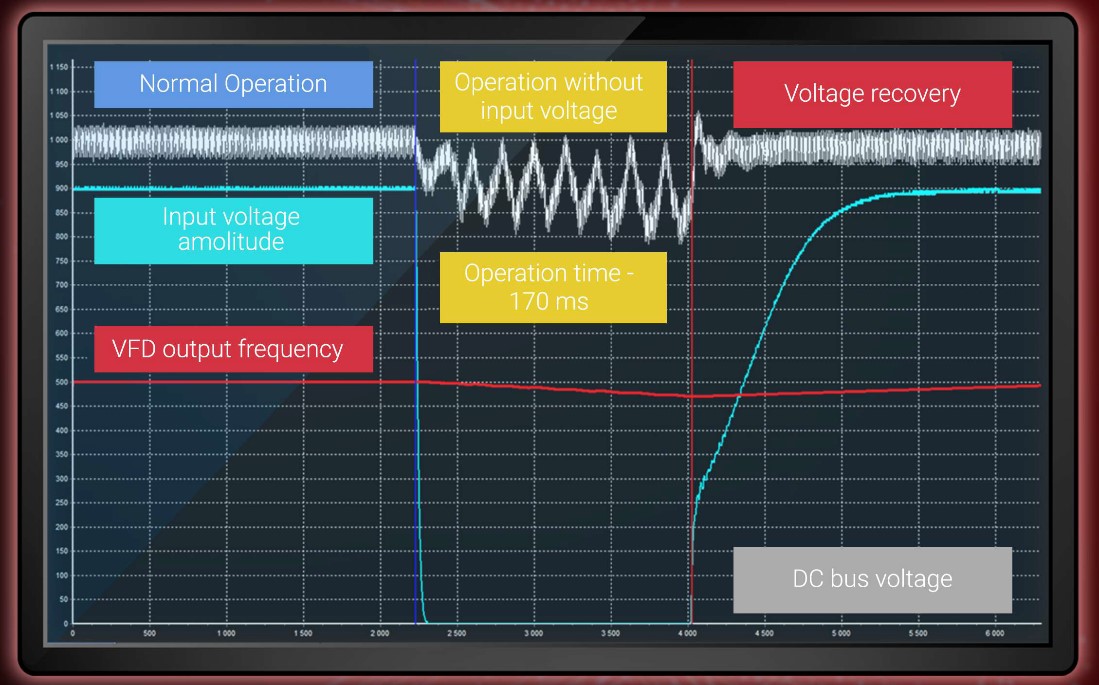

The kinetic advance algorithm ensures stable operation of the Triol variable frequency drives in the event of deep and unbalanced supply voltage sags, and even when the supply voltage is completely lost. In the kinetic buffering mode, the variable frequency drive serviceability is maintained using some of the kinetic energy of the rotating mechanism, with the subsequent instantaneous return to the set operating mode of the mechanism at restoration of power supply. The time of operation of the frequency converter in this mode for stand roll drives can be 5–10 periods of mains voltage. Oscilloscope of the Triol VFD operation when the supply voltage fails:

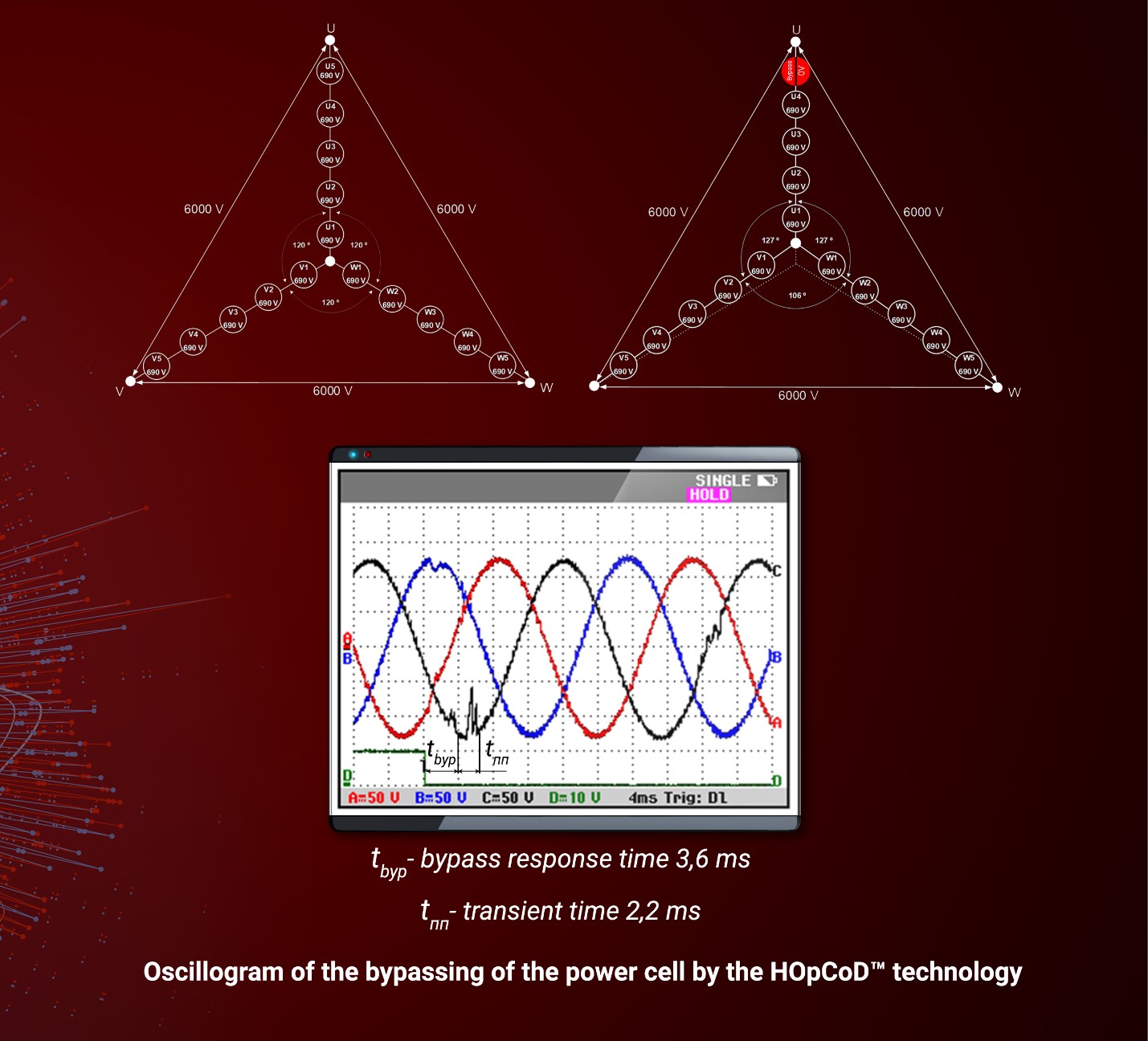

The bypass of the power cell ensures continuous operation of the variable frequency drive even if it is partially damaged. Triol Corporation offers a highly reliable bypass solution for a failed power cell in less than 4 ms. This is made possible by the unique, patented HOpCoD™ technology. The fast and reliable bypass of the power cells allows the variable frequency drive to remain operational, quickly restoring torque and speed to the rollers in the rolling mill, thus preventing process stoppages without compromising the quality of the finished product.

Fan redundancy allows the variable frequency drive to remain operational even if up to 50% of all fans fail. Full fan redundancy is provided in the ventilation system. In the event of a fan failure, the remaining fan in operation ensures that the excess heat is removed. Under each fan there is a gravity louvre unit, which is opened by the air flow when the fan is running. If one of the fans fails, the gravity louvres close, allowing the cooling air to circulate as intended.

2. Integration with automated process control systems

Integration with automated process control systems is ensured by binary and analogue inputs/outputs as well as serial communication ports with Ethernet, Modbus RTU, and Profibus (optional) protocols. The AT27 variable frequency drives are adapted to operate in conjunction with a process control system to provide the full functionality of the rolling mill stand roll drives:

- energy-saving control of the roll drive;

- elimination of shock loads of rolled metal when passing the stand;

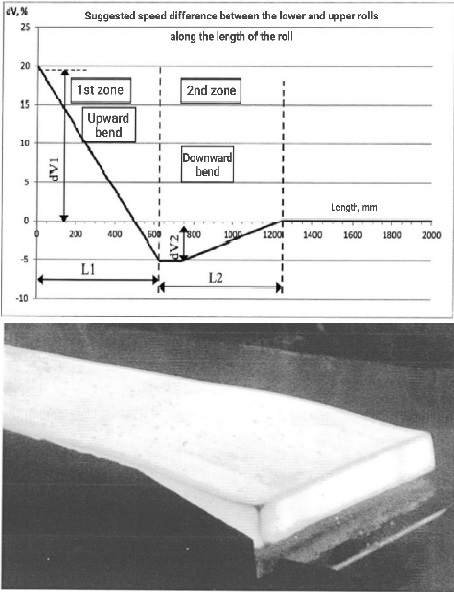

- provision of skiing algorithm ("bending down" and "bending up") of the beginning of a plate fed into the stand;

- ensuring of master-slave mode for twin-drive stands;

- reverse rolling of the sheet;

- spindle positioning.

3. Extending the life of the equipment

Vector control with proprietary torque limiting and motor speed control algorithms in Triol variable frequency drives provides reliable motor protection against motor overload and shaft breakage, specified starting torque, fast response to load changes on the motor shaft without loss of set speed, and accurate maintenance of the set speed. Starting at a current below the rated current allows the use of motor and variable frequency drive power cables with a smaller cross section, reduces wear and tear, and extends the life of the stand roll drive, consequently reducing the implementation, maintenance, and repair costs of the rolling mill. If a sheet of rolled metal enters the rolls, the variable frequency drive maintains the set speed of the roll, compensating for any shock loads, thus limiting wear on the equipment and ensuring the required rolling quality and thickness of the sheet.

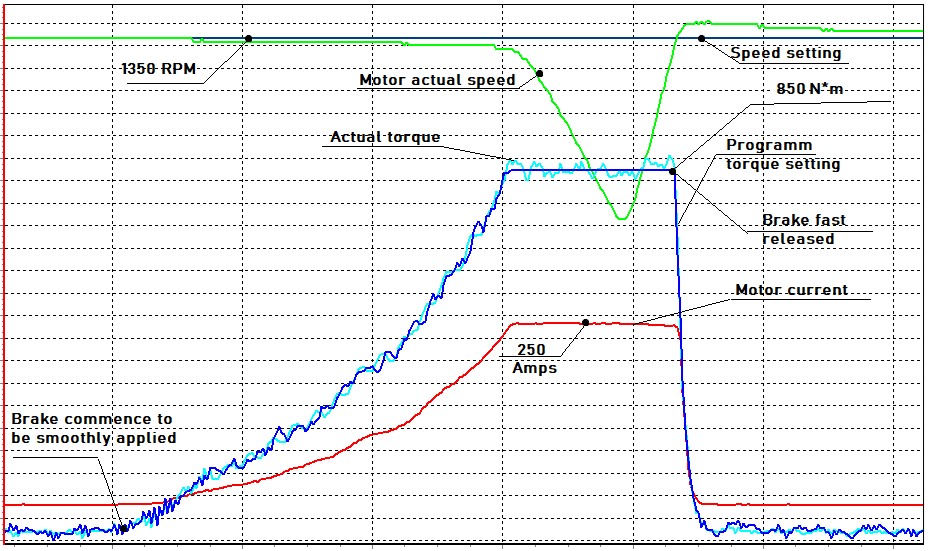

Torque limitation algorithm

The brake application and release at 200% torque limit setpoint without shaft block Precise maintenance of motor torque and speed ensures that the set speed at variable load is maintained until the load limit moment is reached, after which the motor speed is reduced when the torque limit algorithm is triggered, allowing the rollers to remain operational in the event that the load on the machine has been exceeded.

4. Rolling direction reversal and spindle positioning

Spindle reversing and positioning provides the option of changing the rolling direction in the mill, thus reducing the size of the mill and increasing its productivity. It ensures that the spindle is positioned in the specified position for roll change, by precisely working out rolls speed change during positioning.

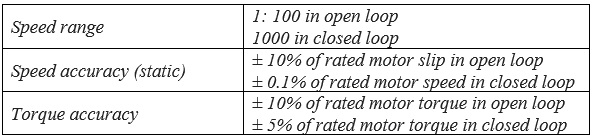

5. Energy optimization and electromagnetic compatibility

The dual power conversion in the Triol AT27 variable frequency drives eliminates the negative effects of mains voltage sags, fluctuations, and asymmetries. Triol AT27 medium-voltage variable frequency drives are fully compliant with IEEE 519 without the need for additional input filters and reactive power compensators.

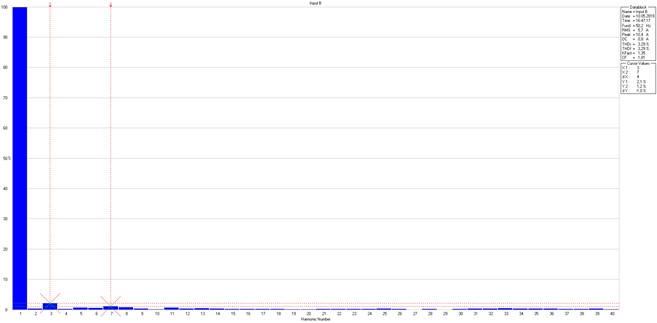

Harmonic spectrum of the AT27 input current

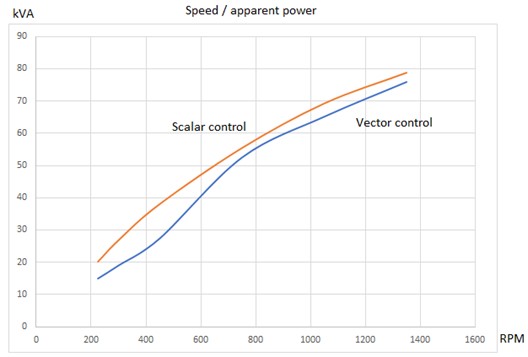

The total THD of the current draw is less than 5%. The vector control algorithm with magnetic flux optimization of the stand roll drive motor reduces the total power consumption of the motor and, together with the process optimization, leads to a reduction in the cost of the products produced. The graphic presents the result of measurement of the apparent power on different frequencies with the rated current.

Energy consumption decrease

6. Working in high dust and conductive dust environments

The Triol AT27 MV line with IP66 (NEMA4) protection is the solution for applications with high and very often conductive dust content. The variable frequency drive has a dedicated cooling duct, which ensures trouble-free and reliable operation of the frequency drive even in the most difficult conditions.

7. Effective control in twin-engine mode

The master-slave algorithm makes it possible to synchronize the operation of the two roll drives in the same stand, via one control channel from the ACS (automated control system), which not only enables loads to be distributed evenly between the rolls, but also sets the required speed difference for the required skiing compensation of the bend when the sheet is fed into the stand.

8. Placement in a limited space.

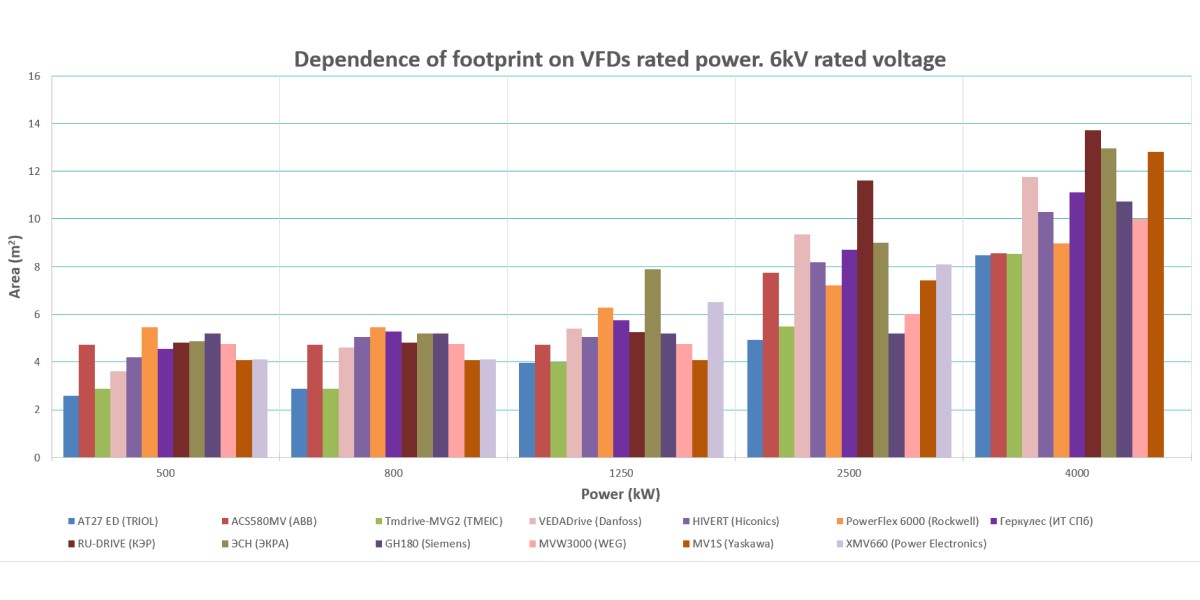

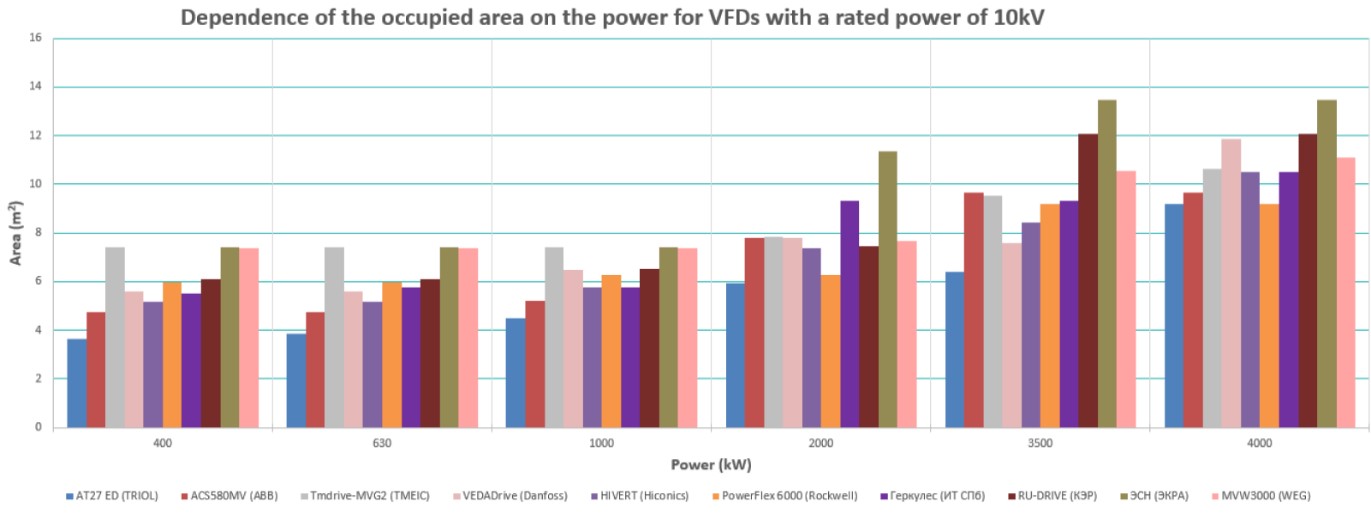

The Triol AT27 VFD ED line has the smallest dimensions in the world among variable frequency drives of its class at 6-11 kV!

The AT27 ED line variable frequency drives save not a few tens of centimeters but on average 25–30% of the area occupied by the VFD.

9. Adaptation to local ventilation and equipment service possibilities

The modular design of the AT27 VFD enables the air filters to be cleaned and replaced without stopping the drive while ensuring personnel safety, and repair times are minimized by the advanced design and interchangeability of power cells. The location of the cooling fans exclusively on the roof makes it easy to arrange the heat dissipation of the Triol VFD by means of duct connections directly to the roof of the drive around the fans. The heat generated by the drive during operation will not heat up the room, but will be dissipated immediately, thus ensuring long and trouble-free operation of the unit.

Triol VFD – a reliable and cost-effective solution!

Don’t miss your elegant solutions!

- Product news

- Events

- Discounts

More news

|

Google

Google